We specialize in the design and production of key air treatment components for air handling units and rooftop units.

All our products fully correspond to the dimensions of components commonly used on the market and are 100% equivalent in terms of efficiency and performance.

The components we design, and produce are subject to continuous improvement. Their technical parameters are guaranteed by independent certification bodies.

Manufacturing & stocking

localy in Georgia (US)

Local production and testing. Full production and delivery traceability. Competitive pricing,

fast order fulfillment.

How did we become a reliable partner?

2004

HVAC component business in Poland, Europe.

2014

Lore lipsum

Developed unique, patent-pending wheel winding technology.

2018

Swiss financial fund acquired our operations in US and Poland to further develop technology and global growth – beginning of Swiss Rotors Group.

USA Office

3535 Gravel Springs Road Ext.

Suite 203, Buford, GA

2020

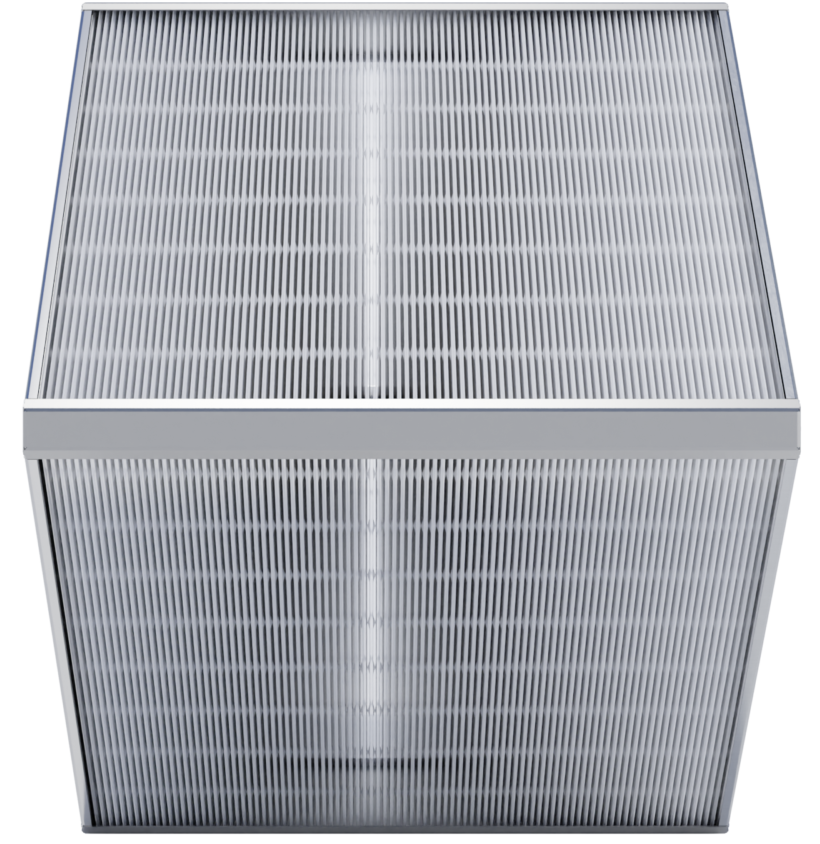

Eurovent certification for Energy recovery wheels and counterflow heat exchangers.

2024

Swiss financial fund acquired our operations in US and Poland to further develop technology and global growth – beginning of Swiss Rotors Group.

USA Office

3535 Gravel Springs Road Ext.

Suite 203, Buford, GA

2024

HVAC component business in Poland, Europe.

2022

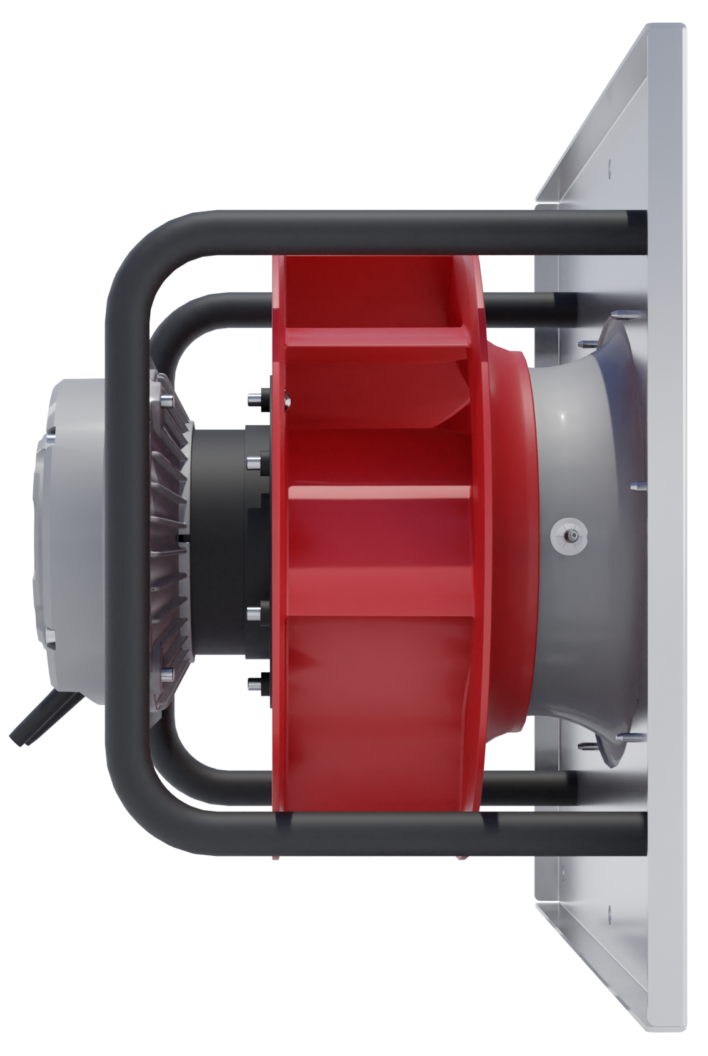

High efficiency EC Fan Sets with polymer and aluminum impellers.

2023

SFC – new range of Energy Recovery Wheels

EC Fans certified by AMCA

EC Fans up to 560 mm

How do we operate

Local production and testing. Full production and delivery traceability. Competitive pricing,

fast order fulfillment.

Lean Management

It is a system that interconnects all processes taking place in our company. It is a tool that allows for quick exchange of information within our organization, and thus for permanent, quick implementation of new solutions as well as improvement of those already implemented.

Sustainability

When designing new products, improving existing ones and implementing new processes in our company, we pay great attention to how they will affect our environment.

That is why we choose solutions that will allow us to achieve our business goals while maintaining our social responsibility to the communities that we serve.

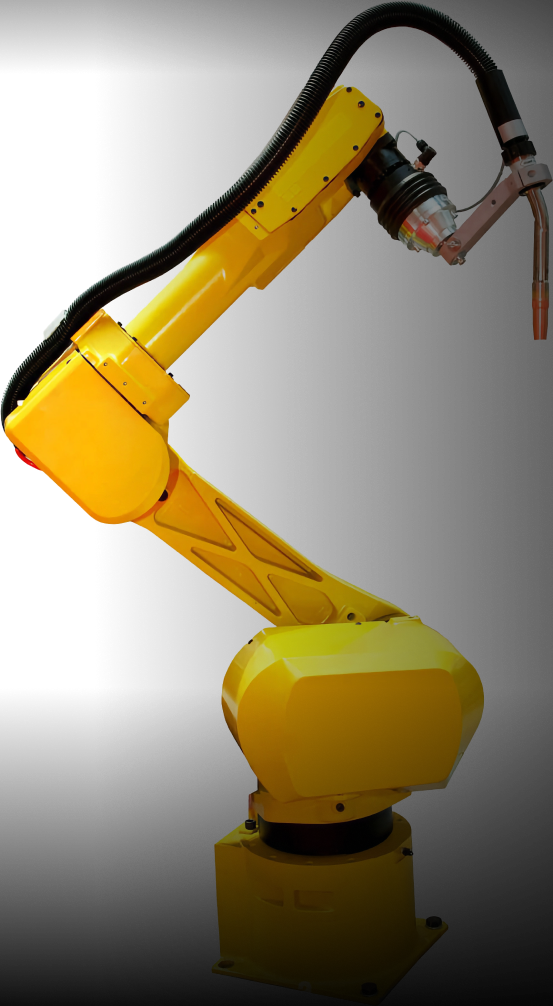

Automated & Robotized Production

To ensure full repeatability of the components we produce, we have implemented highly automated production lines with cutting-edge automation solutions.

All this to eliminate the human factor from these production activities, where the key issue is the precision of execution and validation of the correctness of assembly activities.

Fan Performance Reliability

To ensure full repeatability of the components we produce, we have implemented highly automated production lines with cutting-edge automation solutions.

All this to eliminate the human factor from these production activities, where the key issue is the precision of execution and validation of the correctness of assembly activities.

Acredited AMCA Lab

We have installed a certified AMCA test station, where we test the performance and of our fans based on the guidelines of AMCA 210 – the default standard for the most recognized fan certification in the world.

Our lab is accredited by AMCA Certification.

Where are we located?

We design and manufacture locally… to be as close as possible to our customers and the markets that they operate. So as to fully understand their requirements and follow changes in regulations.

USA Office

3535 Gravel Springs Road Ext.

Suite 203, Buford, GA

Poland Office

Rumska 18

81-198 Dębogórze

USA Office

3535 Gravel Springs Road Ext.

Suite 203, Buford, GA

+1 470 266 6546

support@example.com

Poland Office

Rumska 18

81-198 Dębogórze

+48 66 505 19 41

support@example.com