Today, mechanical ventilation systems are an indispensable element of building equipment, regardless of their purpose. They are used in practically all newly built facilities, as well as in older ones, which were built at a time when our needs for comfort resulting from air quality were not as high as today, or we simply didn’t have the appropriate technical solutions to ensure this comfort. When deciding to use a more or less complex ventilation system, we always ask ourselves about the costs associated with it – both those that we have to incur in order to install such a system in the building, as well as the latter – resulting from their subsequent operation. Having a general knowledge of how the ventilation system is built, how it works and what energy carriers it needs to be able to fulfill the task set for it, we realize that the two above-mentioned types of costs are closely related to each other. Here it turns out that a wisely planned investment in an optimized ventilation system may translate into a subsequent reduction in the costs associated with its use.

What exactly generates the costs?

Whenever we consider a mechanical ventilation system based on a network of ventilation ducts handled by a supply and return Air Handling Unit (or even a Rooftop) with indirect heat recovery, we see a few key costs necessary to make the entire system work:

Therefore, it is worth looking at the interrelationships between these costs to understand how changing one of them may affect the others. Considering that our entire analysis focuses on the air handling unit – or more precisely on the role played by the heat recovery systems used in it, we will look at everything from its perspective.

- The price of the Air Handling Unit itself – strictly dependent on the size of the device, its performance and configuration. It is worth remembering that the possible indirect heat recovery system used here has a considerable impact on the cost of the device itself,

- The cost of electricity used to power our AHU fans and their other components,

- Price of peripheral devices for the preparation of heat and cold carriers for the Air Handling Unit – let’s assume that it is a local boiler that prepares heating water and a chiller. In the case of a Rooftop – these devices will be a part of it – but let’s remember, that most of them will affect the price of the entire Rooftop unit as well,

- The cost of operating our boiler and chiller – strictly dependent on the heat or cooling capacity needed to be secured. The more heat or cool is recovered– the less capacity from the boiler or cooler needs to be supplied.

The size of the Air Handling Unit

The size of the Air Handling Unit (or a similar one like a Rooftop) used depends mainly on the volumetric airflow rate that must be supplied to the ventilation network of the handled building – this in turn results, of course, from the size of the building and its utility character. However, for the same airflow rate, we can use a smaller or larger AHU (with a lower or higher cost of its purchase itself). What will it do for us?

Smaller Air Handling Unit

- it is a cheaper device, but operating at slightly higher airflow speeds (resulting from a smaller unit’s cross-section). This entails an increase in airflow resistance through its individual air treatment components (including the possible heat recovery system), thus increasing the electric power consumption of its fans – and ultimately the operating cost resulting from the ventilation of the building itself.

- it can accommodate a relatively small heat recovery system (counterflow heat exchanger, HexWall system, or rotary heat wheel), the performance of which, at the assumed airflow, may not be satisfactory.

Larger Air Handling Unit

- guarantees a reduction in electric power consumption by fans due to the reduced airflow resistance through AHU components – thus it allows us to reduce the expenses incurred by us for the ventilation of our building.

- can be equipped with a heat recovery system with larger dimensions – and thus – better recovery performance. This difference will be noticeable as a reduction in the demand for heat and cool capacity supplied to the unit for the final heating or cooling of the air supplied to the building.

Heat Recovery System

As noted above, the maximum size of the applied heat recovery system strictly depends on the size of the AHU to which it is to be installed. This size is determined by geometric considerations – the recovery system must fit well in the air handling unit so that it doesn’t protrude from it. Going further – if we compare two heat recovery systems of different sizes working with the same airflow and the same air parameters, the bigger one takes the top, satisfying us with its efficiency as well as lower flow resistance. What we like less is the price of such a system and the price of the entire air handling unit in which it will be used. Of course – a larger system and larger AHU will cost more. A smaller AHU with a smaller recovery block (or without the heat recovery at all) will save some money in our pocket. But, as it turns out – this saving is only apparent.

Mutual relationship of investment costs

We already know about air handling units that their price is largely dictated by the maximum airflow rate that the unit is capable to handle, which goes together with its size. Simply put, a larger unit has cost more and there is nothing we can do about it. This “capacity-size-price” relationship considers also all of the auxiliary devices supporting the air handling unit itself, such as boilers or chillers. Here, too, there is a rule that the more heat or cold we want to prepare – the larger and more expensive device we have to buy.

At a time when the use of systems that recover heat or cold from exhaust air was a kind of novelty on the market, the source of concern was often the cost of a supply-exhaust Air Handling Unit equipped with a rotary or cross-flow exchanger (today successfully replaced by a counter-flow exchanger or a HexWall module), which in relation to a simple supply AHU was much higher. For many of us, the numbers might seem daunting and often they decided to resign from subsequent operating savings in favor of reducing the cost of the AHU itself at the time of its purchase. However, the analysis of investment costs focusing solely on the air handling unit with or without heat recovery was burdened with a significant error, as it did not allow to see other savings resulting from the change in the size and performance of devices supporting the unit itself.

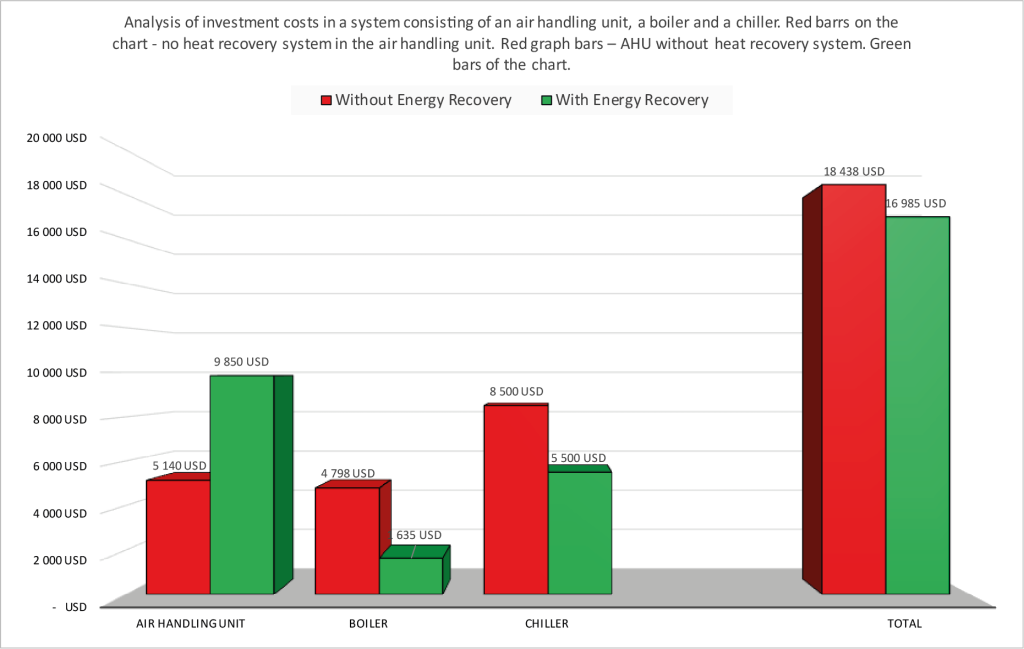

| Item | Without Heat Recovery | With Heat Recovery | Balance |

| Air Handling Uni | 5 140 USD | 9 850 USD | -4 7140 USD |

| Boiler | 4 798 USD | 1 635 USD | 3 163 USD |

| Chiller | 8 500 USD | 5 500 USD | 3 000 USD |

| Total | 18 438 USD | 16 985 USD | 1 453 USD |

Specifically speaking – to get a full picture of the investment cost, it is worth including the cost of the boiler and the chilled water unit (or other peripheral devices supplying the unit with heat and cold) to the analysis. A simple table can provide the first full picture of these costs. However, plotting the same data in the graph clearly shows us the sum of the investment costs for options with or without indirect heat recovery.

The prices shown in the chart are indicative in order to show the method of analysis of investment costs and their interrelationships. They are not based on the actual prices of the devices of a specific manufacturer.

How will the investment be transformed into broadly understood operational savings?

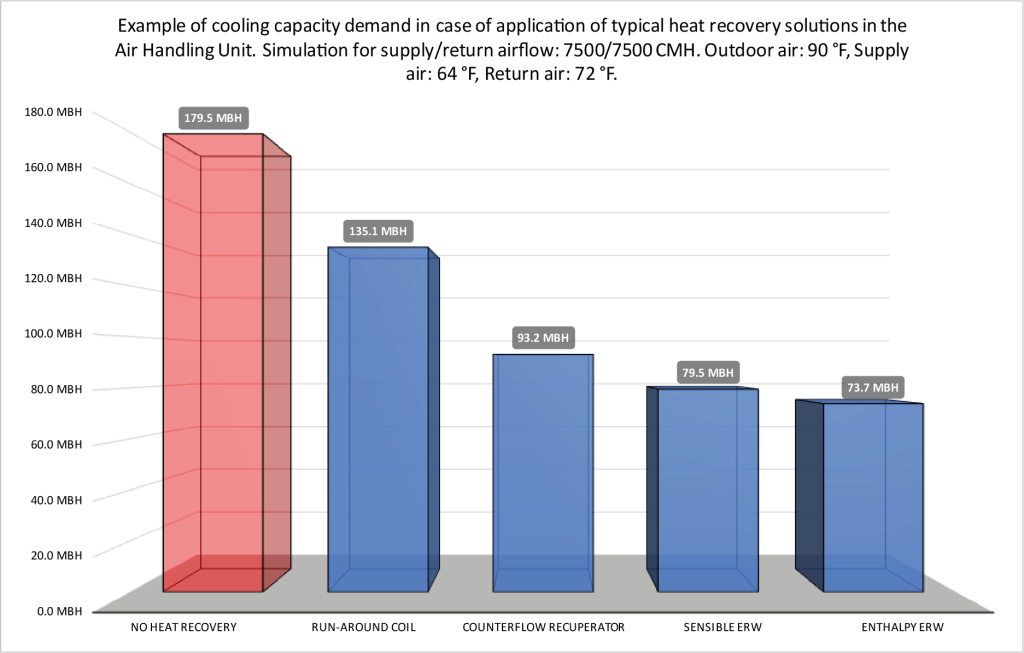

The answer to the question posed in the title of this chapter seems simple. The core of our savings in the following years of using the ventilation system equipped with an indirect heat recovery system will result in a simple relation from a significant reduction of heat and cold capacity that must be delivered to the air handling unit. And the difference in this power demand will be exactly the same as the amount of heat recovered.

And if we combine these operational savings with investment savings – it turns out that the legitimacy of using high-efficiency solutions allowing for heat recovery in various ventilation devices – air handling units or others such as Rooftop – is absolutely unquestionable.

The chart above shows us that:

- The purchase cost of supply-return Air Handling Unit equipped with an indirect heat recovery system is higher than a device not equipped with such a system,

- The cost of purchasing a boiler (or another device supplying heat to the AHU, eg a gas furnace) is reduced if the heat recovery system is applied in the AHU. This is due to the fact that the AHU with heat recovery shows less demand for the heating capacity, which results in the necessity to purchase a boiler with lower power and lower price.

- The cost of purchasing the chiller (or another, for example, a refrigeration compressor unit) – decreases similar to the purchase of a boiler. Cooling recovery from the exhaust air (in the case of a heat recovery unit) results in lower cooling demand, and therefore the need to purchase a smaller chiller.

From such an analysis, we can see that a broader look at investment costs – not limited to the AHU itself – allows achieving savings when purchasing devices. In this particular case, the total saving is $ 1.453.