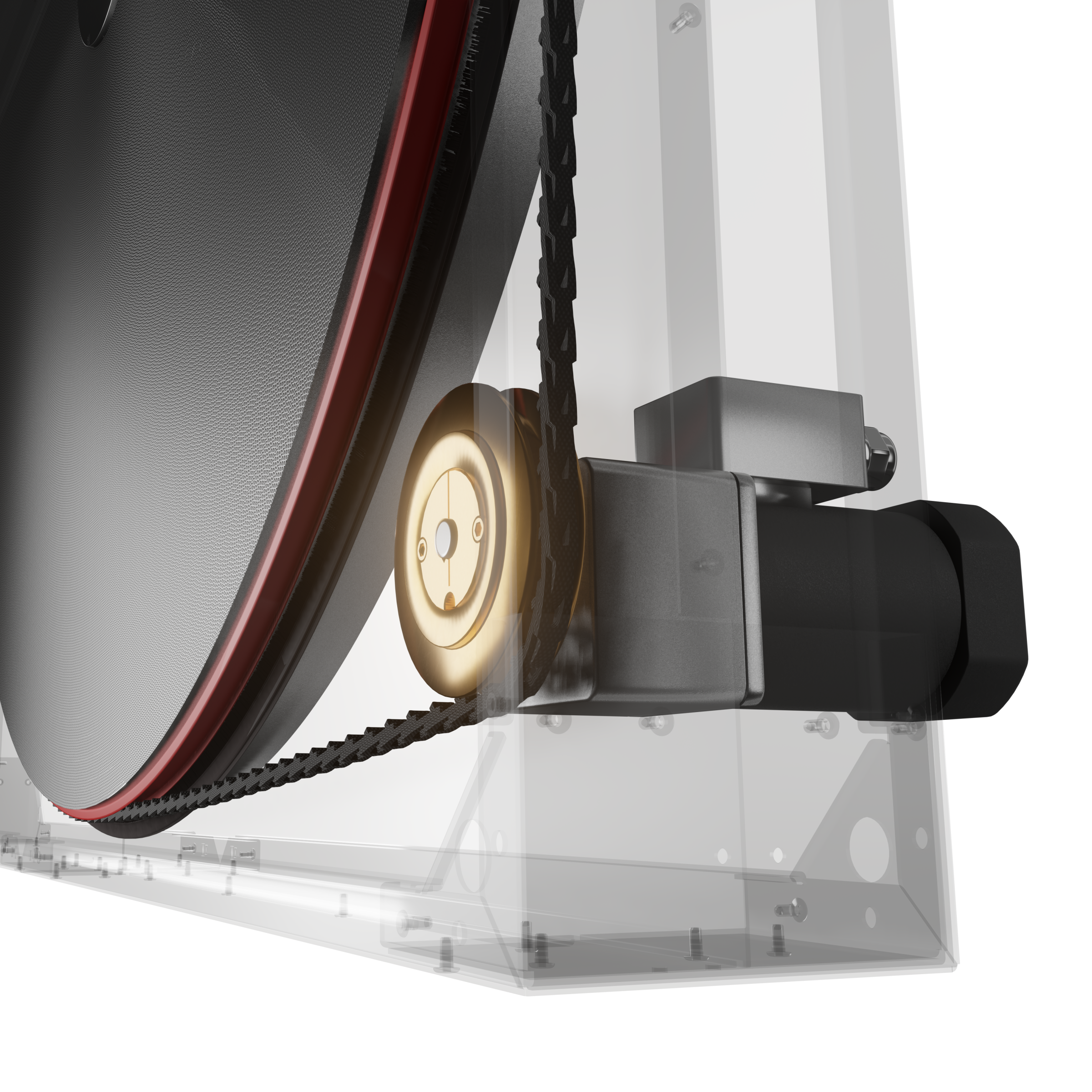

Energy recovery wheels, which, despite the fact that they cannot be used in all ventilation systems, are generally considered to be the best of the commonly used heat recovery systems in air handling units. In any comparison, their performance outweighs other typical solutions (core heat exchangers, run-around coils, etc.). When deciding to apply wheels from any given manufacturer, our first instinct is usually to focus on the declared parameters of the heat recovery process – both sensible and latent. In the next steps, we take a closer look at the price, terms of cooperation with the supplier, lead time and warranty conditions. However, it turns out that along the way we forget about another, purely engineering evaluation criterion.

What is the thing we forget to evaluate?

What usually remains beyond our interest is the fact that energy recovery wheels are devices in which, in addition to advanced mechanical and thermodynamic solutions, another field of technology – mass transfer – is used. We are talking about various hygroscopic coatings that are used to coat the exchanger foil in order to obtain maximum efficiency of moisture transfer between the air streams. Being aware of their use, we are used to assessing their “quality” only in terms of how a given exchanger copes with the transfer of latent heat. It does not occur to us that these coatings may have different recipes, and the technology used to apply them is an important factor determining how our wheel shall work throughout its long-term operation.

What to ask...

Starting from the fact that the hygroscopic material used as a medium to transfer moisture in energy recovery wheels is applied to the substrate (usually aluminum foil) using various technologies, the question arises about how durable this coating is and at what rate it will degrade. This question becomes particularly important when we realize how difficult the operating conditions of the coating and the entire wheel can be. On the one hand, we have an intense air flow with a constantly changing direction, and on the other hand – alternating operation in conditions of strong differences in temperature and humidity of the air involved in the recovery process. Additionally, typical ambient atmosphere contains usually aggressive chemical compounds and has acidic characteristics (air and rain pollutions). Very often the incoming air brings airborne pathogens (viruses and fungi). Last but not least, airborne soot is responsible for further downgrading of the performance of the coating.

The gradual degradation of moisture recovery performance (humidification of the supplied air in winter and dehumidifying it in summer) is a well-known phenomenon. The factors described above constitute the natural operating conditions of the exchangers and it is difficult to blame them. Therefore, the reasons for insufficient longevity should be found solely in the hygroscopic coatings themselves, from the type of substance used to the method of application and its final structure.

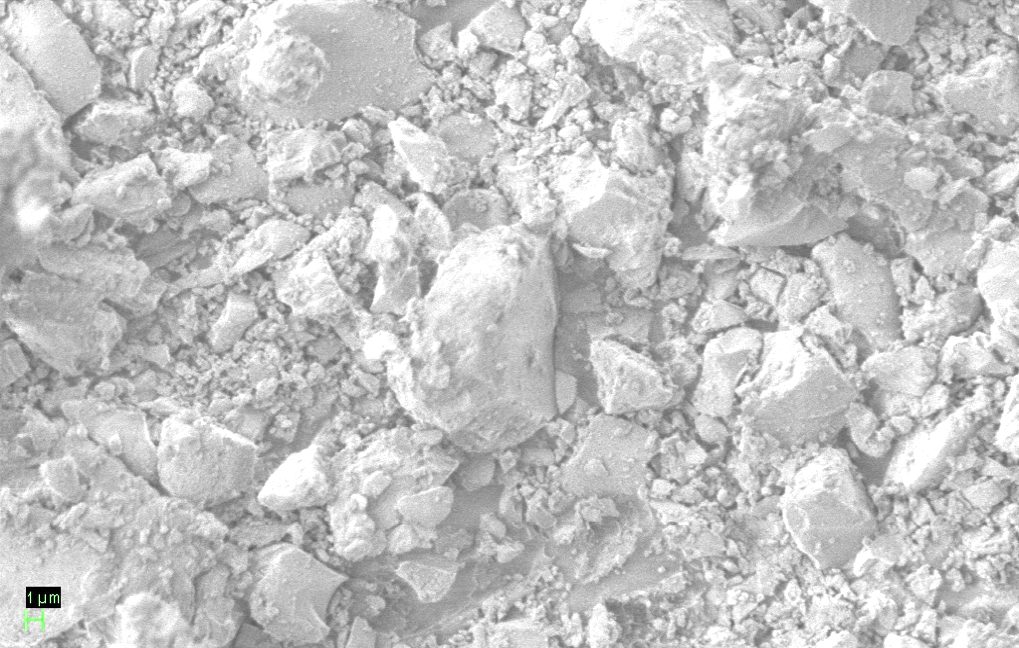

Typical hygroscopic coatings

It turns out that the commonly used substances constituting the hygroscopic layer of energy recovery wheels are not much different from those used in construction and general painting applications. Hygroscopic coatings created using them are usually characterized by a random final structure and relatively high roughness. Ultimately, this translates into relatively low water transfer efficiency and poor mechanical resistance resulting in a high degree of dusting.

What was the goal of our research?

Taking into account the above-mentioned operational problems of hygroscopic coatings, we started a multi-year research project. When developing the best hygroscopic coating, we divided our work into two key aspects:

- The first one was to create a recipe for the hygroscopic material itself in terms of chemical composition and numerous technological procedures used to prepare it. All this to ensure that the material used shows the best performance in transferring moisture while ensuring long-term durability.

- The second one is the development of the best technology for applying this material to a base, which is usually a thin aluminum foil. The goal here is to fix the coating to the base as durably as possible and to obtain even coverage.

What have we achieved as a result of our research?

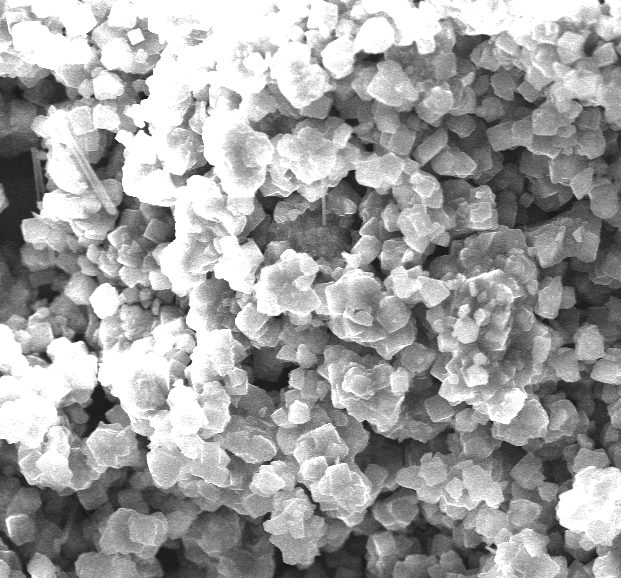

We started our research on the ideal hygroscopic coating with the assumption that the only substance we want to transfer between air streams is water – a chemical compound whose molecule has a kinetic diameter of only 2.65 angstroms (1Å = 1.0 x 10-10 meters). Therefore, we used a specially developed Zeolite as the sorption material: a synthetic, activated aluminosilicate with pores with a diameter of 3Å, i.e. slightly larger than the diameter of the mentioned water molecule. Based on this material group, we have selected optimal one in which the reversible adsorption process called Cyclic Ultra Rapid Sorption/Reversible Fast Sorption is carried out. This molecular sieve has perfectly shaped crystals that are characterized by excellent sorption capacity on one hand, and excellent mechanical strength on the other.

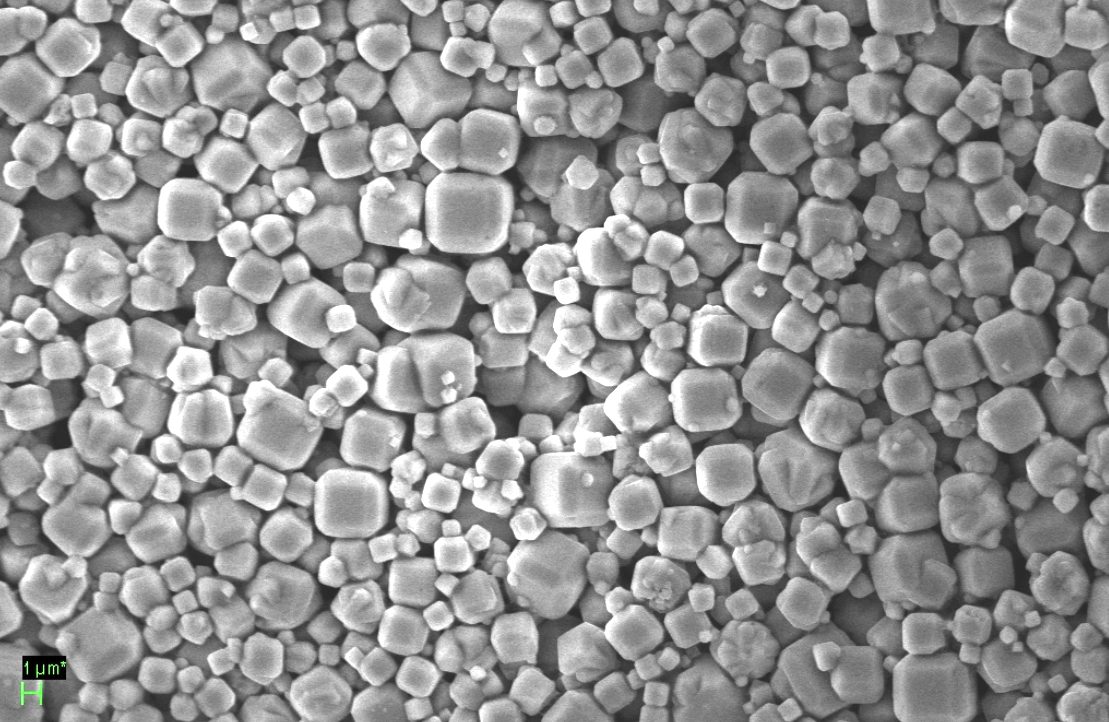

Having selected a material that meets our expectations in terms of thermodynamics and mechanical resistance, we moved on to the next phase of the project – creating the best possible technology for applying a zeolite layer to the aluminum foil constituting the core of our wheel. We have created a unique technique that creates a multi-layer 3D structure with high density and high susceptibility to penetration by water particles. The layered structure created in this way is characterized by:

- High mechanical strength, or more precisely, resistance to the erosive effects of flowing air, moisture and possible solid contaminants.

- Low thermal resistance achieved by creating a dense multi-layer structure between individual coating layers, in which the unfavorable phenomenon of thermal blocking does not occur.

The final result of our research is an innovative hygroscopic coating that guarantees long-term operation with non-deteriorating heat recovery parameters. A coating in which we used the most advanced technologies from the NANO family – focusing on the hygroscopic material itself, and MICRO – involved in the most optimal application of the zeolite we have developed.